MICHAEL de FOREST

|

|||||

|

SUTURE SERIES VESSELS

|

|||||

FURNITURE SUTURE SERIES BLOG copyright 2006-10

|

In another variation of the suture series Michael de Forest developed a new constructive method of creating new forms from individual, discrete pieces made somewhat at random and then assembled. He used a clay sculpture of a torso, that was fragmented to make molds for the shapes that make up the collection of vessels you see here. |

||||

|

Messenger: Faithful, Communicative, Traveler bent wood veneer, incised line carving, milk paint, seine line |

|

||||

|

Butterfly: Metamorphosis, Carefree, Transformer bent wood veneer, incised line carving, milk paint, seine line |

|

||||

|

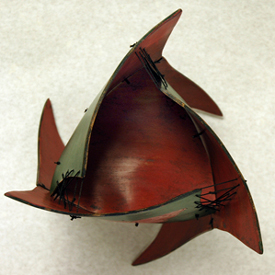

Meoto-iwa: Commitment, Tenacity

bent wood veneer, incised line carving, milk paint, seine line |

|

||||

|

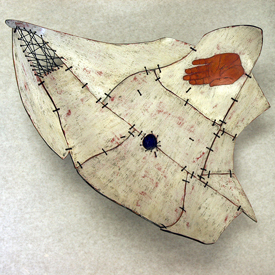

Left Palm Down: Life, Creative, Healing

bent wood veneer, incised line carving, milk paint, seine line |

|

||||

|

Lucinda in Repose

bent wood veneer, incised line carving, milk paint, seine line |

|

||||

|

De Forest sculpted a female torso in clay in order to create the irregularly curved molds to bend the wood that would eventually be sewn into the vessels. The torso surface was arbitrarily divided into sections by spreading paper over the surface following the compound curves until the paper either started to fold or tear. This represented the largest area that veneer would bend before buckling or splitting. Each piece of paper was then cut and taped to the sculpture. The next paper was spread out next to it, and the next, etc., until the entire sculpture was covered with 137 pieces of paper. He cut into the sculpture whereever two pieces of paper touched and created a border. 1” wide waxed paper strips were put into the slots that the cuts created to fashion dams for plaster molds. Once the sculpture was covered with plaster the surface was ground down until the paper strips were revealed. Wooden wedges were pounded between pieces to loosen up each section of plaster and remove them. Tape was put around the edges of the negative plaster molds forming dams to receive reinforced polyurethane to create positive molds. Three pieces of glued veneer are then placed on these positive molds which then go into a vacuum press to bend the wood to the molds. These pieces are then trimmed, assembled temporarily to configure a container or vessel, drilled, carved, painted, and sewn together. |

|||||

| . | |||||

|

|

|||||